Material Handeling

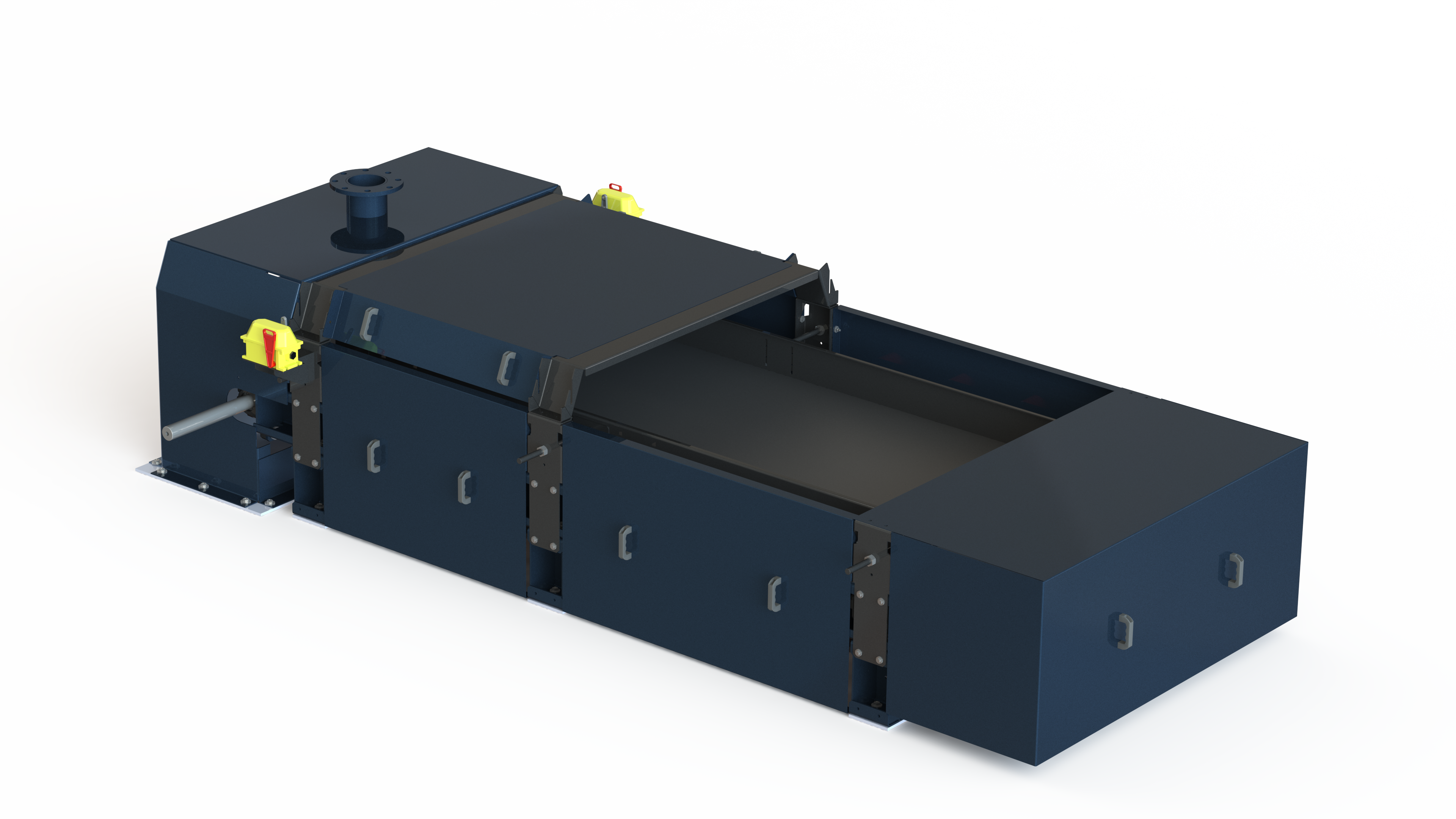

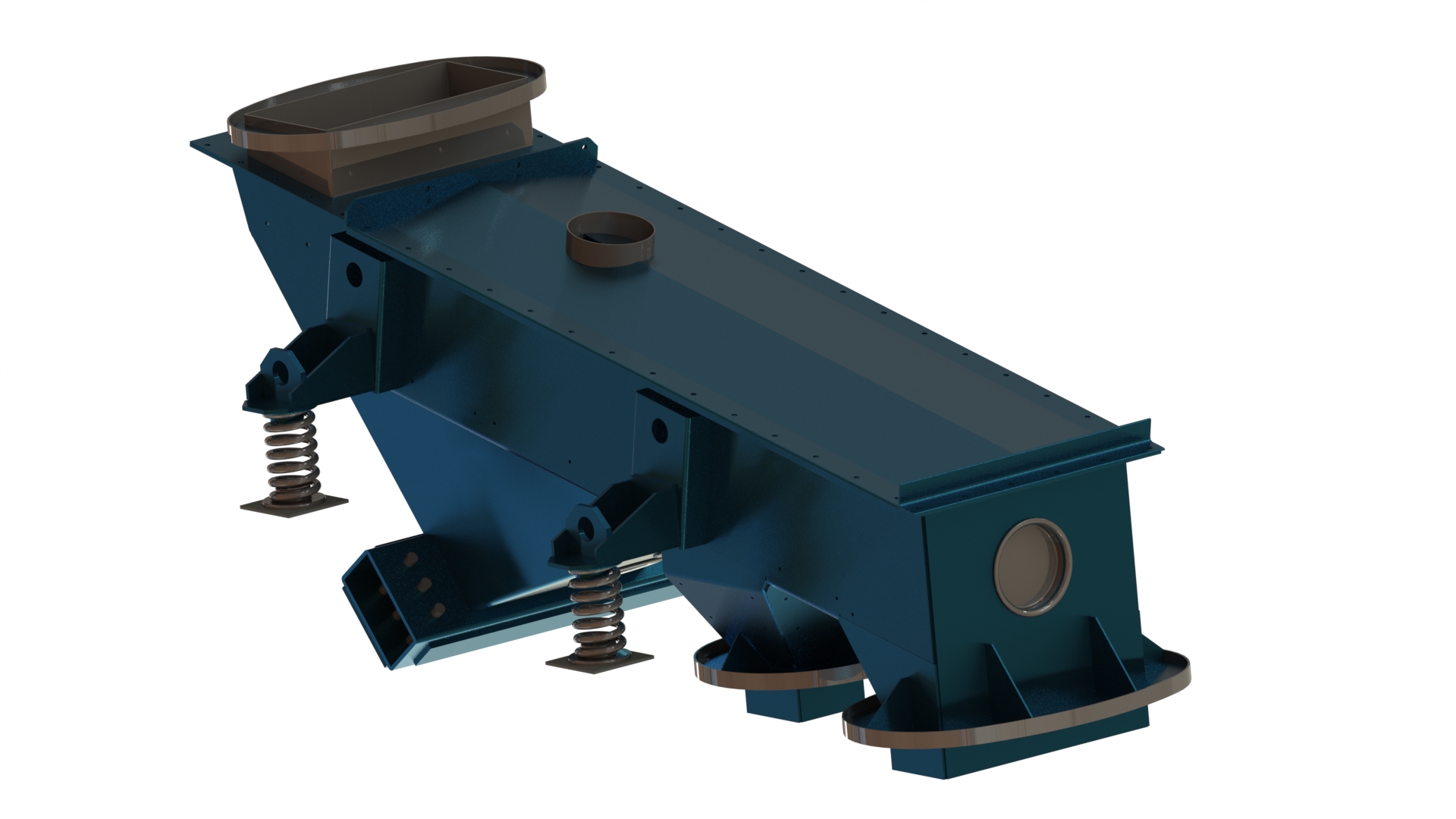

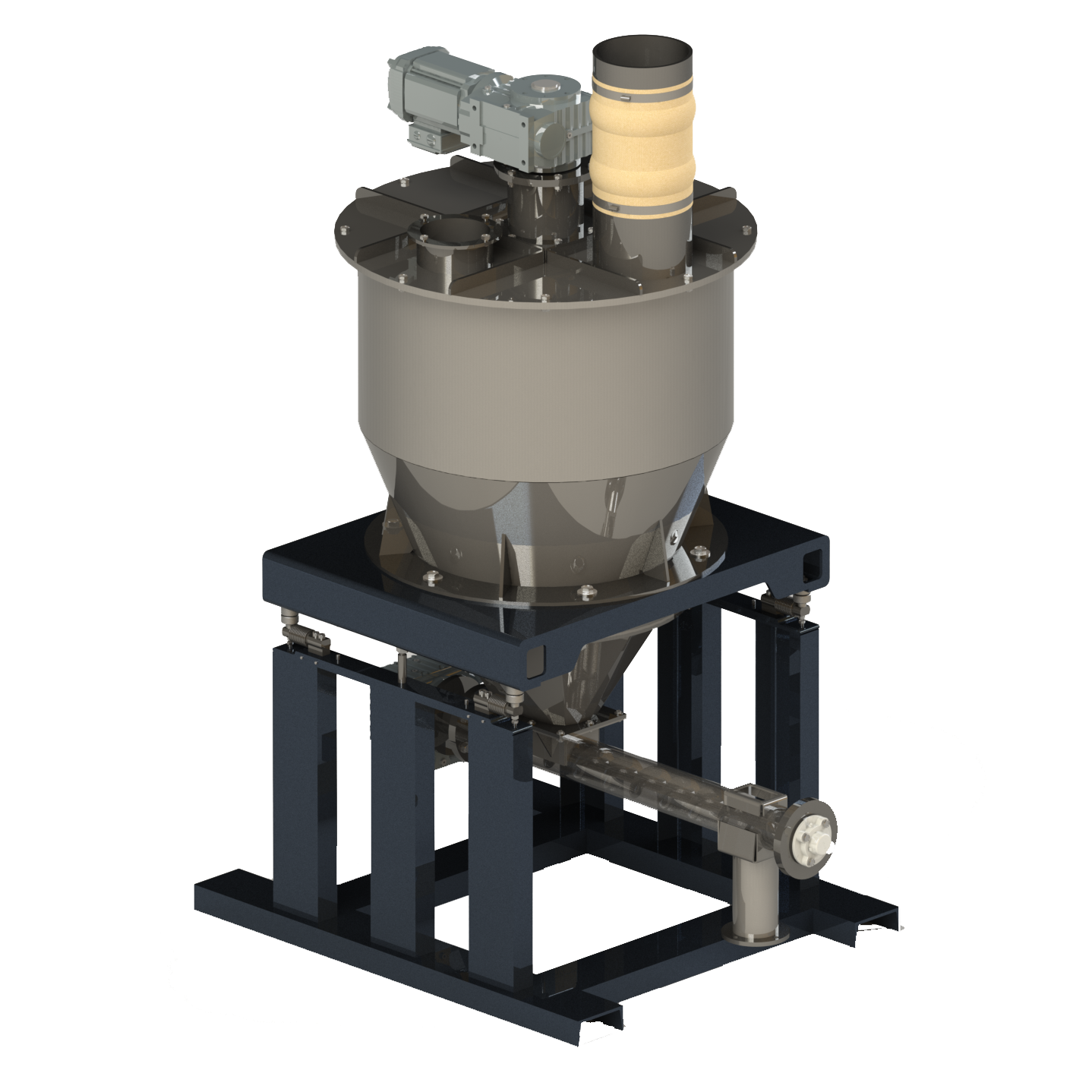

Weigh feeder

- Accuracy (related to actual valve) ± 0.25 to 0.5 % application-dependent System-dependent better than ±0.25 %

- Conveying speed Max. 0.5, dependent on material feed

- Material temperature 80°C with standard, 130 °C and 170°C with special variants

Weigh feeder Introduction

Weigh feeding systems are used to control and measure the flow of bulk materials, ensuring precise and consistent delivery. A weigh feeder System consists of a conveyor belt, load cells, a tachometer, and a controller. The conveyor belt transports the material, while the load cells measure the weight of the material on the belt. The system operates in a closed-loop control manner. The load cells continuously measure the weight of the material on the conveyor belt. This data is sent to the controller, which adjusts the belt speed to maintain the desired flow rate. high-quality industrial weighing systems can achieve accuracies within 0.25% to 0.5% of the full-scale capacity

Weigh feeder Specifications

Weigh feeder AR View